Torsion Motors

Components for economically efficient torsion test rigs

Your benefits with Moog GAT Torsion Motors

Modular delivery range

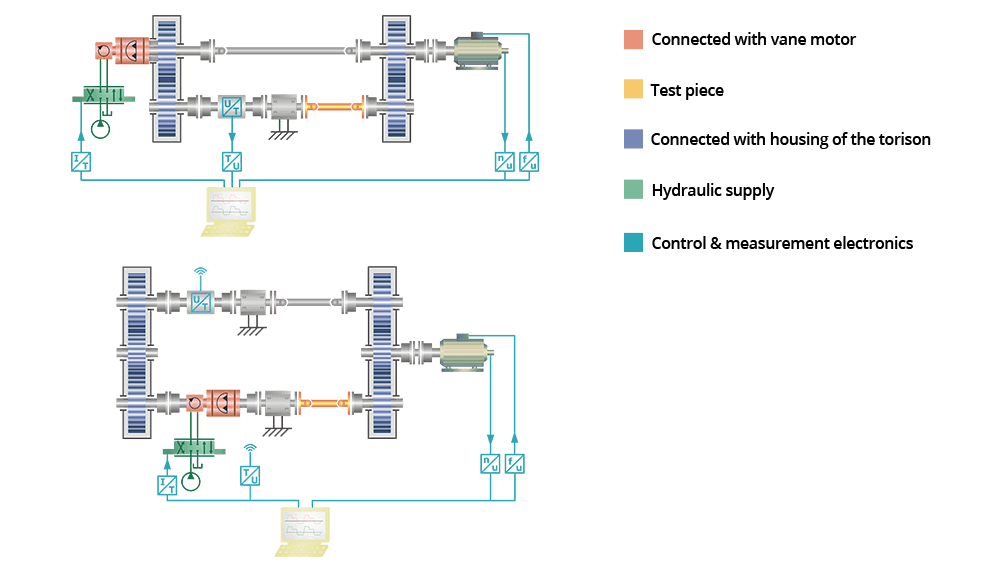

Moog GAT torsion motors are supplied as individual components or as complete torsion system consisting of torsion motor unit, application-specific control electronic s and hydraulic supply. Comprehensive consultation services from concept planning phase to commissioning complement our portfolio.Torsion motors for any testing condition

Moog GAT torsion motors consisting of a basic motor and a GAT rotary union are designed for quasi-static, pulsating and dynamic loads. Speed and torque as testing parameters are controlled independently.Extraordinary profitability

The torsion test rig with mechanical torsion application allows the energy-efficient testing of components at relatively low investment costs. Using a hydrostatic torsion motor in the test rig creates realistic and consistent testing conditions leading to test results very close to real-life conditions.

VM series

The VM series is especially suitable for applications requiring a cost-efficient solution with or without servo-hydraulic system for quasi-static operation up to medium rotational speeds.

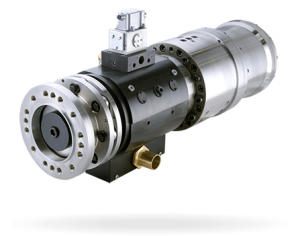

VMC series

The VMC series is especially suitable for applications requiring high resolution, high dynamic range and high primary speeds.

EV/EVC series

For the EV/EVC series, torsion motors VM/VMC are retrofitted with matching components for operation in test rigs. These include, among others, couplings and measuring flanges, but also the installation into a bearing-mounted unit especially suitable for applications with higher speeds and/or dynamically reversing torsion.

Example Torsion Test Rig

The torque motor converting hydraulic into mechanical energy is the core of any torque test rig. Based on our extensive know-how, we can build solutions tailored to the requirements of your test rig in terms of rotational speed and torque. Our components allow testing with static and quasi-static load spectrums as well as dynamic torque induction. High performance density is a characteristic feature of our torque motors, making them suitable for almost any testing condition.

The torque motor converting hydraulic into mechanical energy is the core of any torque test rig. Based on our extensive know-how, we can build solutions tailored to the requirements of your test rig in terms of rotational speed and torque. Our components allow testing with static and quasi-static load spectrums as well as dynamic torque induction. High performance density is a characteristic feature of our torque motors, making them suitable for almost any testing condition.

Torsion motor

Hydraulic supply

Control electronics

Consulting and commissioning

| Preview | Titel | Language | Download |

|---|---|---|---|

|

Brochure Torsion Motors V5 | English |